close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-08 Origin: Site

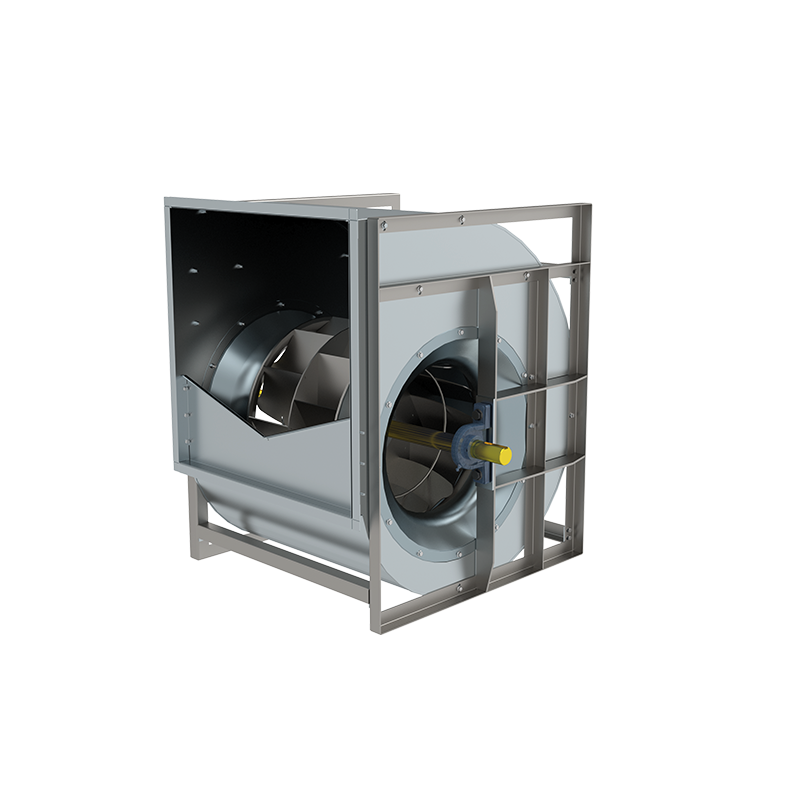

Choosing the right industrial centrifugal fan is essential for your facility. It ensures air quality, temperature control, and worker safety. But with so many options, how do you choose the best one? In this article, we’ll discuss the key factors you need to consider when selecting the ideal centrifugal fan. You’ll learn how to balance airflow, pressure, and energy efficiency without compromising performance.

To determine the required airflow (measured in cubic feet per minute, CFM) for your facility, start by evaluating the volume of air your processes demand. The CFM can be calculated by considering room volume and the desired number of air changes per hour. For example, a manufacturing plant might require higher CFM to keep dust levels low, while an HVAC system needs sufficient airflow for temperature regulation. By measuring airflow accurately, you can avoid oversizing or underperforming fans, which could lead to wasted energy or insufficient ventilation.

Static pressure refers to the resistance encountered by the airflow within the system due to ductwork, filters, and equipment. This is a critical factor when selecting a centrifugal fan, as it determines the fan's ability to push air through the system. A fan with higher static pressure capability is necessary for systems with long duct runs, heavy filters, or equipment that adds resistance. The fan should be able to overcome this resistance without compromising airflow.

Consider the temperature, humidity, and presence of corrosive elements in your facility. For example, a food processing plant might require fans capable of handling moisture, while a chemical plant may need corrosion-resistant materials. Selecting a fan suited to your environment ensures longevity and reliable performance. Fans designed for extreme temperatures or humid conditions will also be more energy-efficient in the long run.

Forward-curved centrifugal fans are designed to move large volumes of air at low pressures, making them ideal for applications where high airflow is required but pressure resistance is low. These fans are often used in HVAC systems, residential ventilation, and equipment cooling. While they are cost-effective and efficient in low-pressure systems, they tend to be noisier and less energy-efficient at higher pressures.

Backward-inclined centrifugal fans are more efficient and produce lower noise compared to forward-curved fans. Their design allows them to handle higher static pressures, making them suitable for demanding applications such as industrial exhaust systems, dust collection, and air filtration. These fans are energy-efficient and maintain consistent performance even in environments with higher resistance. They are the best choice when pressure is a priority, even though their initial cost might be higher than forward-curved fans.

Radial fans use impellers designed to handle debris and particles, making them ideal for environments where material handling or dust collection is required. They are commonly used in applications like pneumatic conveying systems and industrial ventilation. While radial fans are effective at high pressures, they are generally less efficient compared to forward or backward-curved fans, especially in clean-air applications.

When selecting a centrifugal fan, it is essential to match the fan’s airflow capacity (CFM) and pressure requirements to your system’s needs. For low-pressure applications, forward-curved fans are sufficient. However, if your system involves high resistance or requires precise airflow control, backward-inclined or radial fans are better suited. Always evaluate both airflow and static pressure to ensure the fan can operate efficiently under your system's specific conditions.

Energy efficiency is a key factor when choosing a centrifugal fan. Backward-inclined fans are generally more energy-efficient due to their aerodynamic design, which reduces energy loss. While forward-curved fans may be less expensive upfront, they consume more energy in high-pressure systems, leading to higher operational costs over time. To maximize savings, prioritize fans that offer low energy consumption while still meeting your performance needs.

The following table outlines the noise levels and maintenance requirements for different types of fans, helping you select the best fan for your work environment.

| Fan Type | Noise Level | Maintenance Requirements | Efficiency | Application Environment | Technical Specifications |

|---|---|---|---|---|---|

| Forward Curved Fans | High noise | Frequent cleaning, especially in high-pressure environments | Lower efficiency | HVAC, Residential Ventilation | Lower efficiency in high pressure, requires regular inspection and maintenance |

| Backward Inclined Fans | Low noise | Minimal maintenance, durable | High efficiency | Industrial exhaust, dust collection | Stable performance in high pressure, energy-efficient |

| Radial Fans | Moderate noise | Regular checks, especially when handling particulate matter | Moderate efficiency | Material handling, dust collection | Suitable for high particulate environments, requires regular inspection of blades and ducts |

Tip: Choosing a fan with low noise levels can greatly improve the comfort of your work environment, especially in noise-sensitive areas like hospitals or offices.

The material of the fan is crucial for ensuring durability and performance in harsh environments. For facilities exposed to corrosive chemicals or high temperatures, choosing fans made from corrosion-resistant materials like stainless steel or aluminum is essential. These materials can withstand the wear and tear from harsh conditions, reducing the need for frequent replacements or repairs.

Environmental factors such as temperature, humidity, and the presence of corrosive gases can severely affect the longevity and efficiency of centrifugal fans. For example, fans in chemical plants or food processing facilities may be exposed to acidic or alkaline conditions, requiring fans made from resistant materials. Similarly, high-humidity environments demand fans with moisture-resistant features to prevent rust and degradation.

This table summarizes the durability characteristics of different fan designs and materials, helping you consider how fan design impacts its long-term performance and durability.

| Fan Type | Material Selection | Design Features | Durability | Applicable Environments | Technical Specifications |

|---|---|---|---|---|---|

| Forward Curved Fans | Steel, Aluminum Alloy | Simple structure, suitable for low-pressure environments | Lower | Clean air, Residential Ventilation | Sensitive to moisture, requires regular inspection |

| Backward Inclined Fans | Stainless Steel, Aluminum Alloy | High-strength design, suitable for high-pressure environments | High | Industrial exhaust, pollution control | Corrosion-resistant, suitable for harsh environments |

| Radial Fans | Aluminum, Plastic | Strong material handling capacity, suitable for particulate-rich environments | Moderate | Material handling, dust collection | Suitable for particulate environments, requires blade cleanliness checks |

Tip: Choosing durable materials such as stainless steel can effectively extend the fan’s lifespan, especially in corrosive or high-temperature environments.

When selecting a centrifugal fan, partnering with a reputable manufacturer who offers custom solutions and engineering support can be invaluable. Manufacturers with experience in designing fans for specific industrial needs can ensure that the fan meets all performance and environmental requirements. Custom engineering support also allows for tailored solutions that integrate seamlessly into your existing systems.

A reliable vendor should provide comprehensive after-sales support, including installation guidance, ongoing maintenance services, and training for your team. This support ensures that your centrifugal fan continues to operate efficiently and meets all safety and regulatory standards. A vendor with strong after-sales services can help you troubleshoot issues and optimize fan performance throughout its lifespan.

While it might be tempting to opt for the lowest-cost centrifugal fan, it’s important to consider both the initial investment and long-term operational costs. Fans with higher upfront costs, such as backward-inclined models, typically offer greater energy efficiency and durability, leading to significant savings over time. By evaluating the total cost of ownership, you can select a fan that provides the best value over its lifespan.

A thorough cost-benefit analysis will help you evaluate the return on investment (ROI) of different centrifugal fan models. Consider factors such as energy consumption, maintenance needs, and fan durability. While a cheaper fan may save you money initially, its higher energy consumption and maintenance costs may make it a less cost-effective option in the long run. Prioritize fans that offer high performance and low operational costs for the best overall value.

Choosing the right industrial centrifugal fan is essential for maintaining efficient airflow, meeting regulations, and cutting operational costs in your facility. By evaluating factors like airflow requirements, pressure needs, and energy efficiency, you can make an informed decision. Partnering with a trusted manufacturer like Zhejiang Rongwen Fan Co., Ltd. ensures high-quality, custom solutions and after-sales support. Their products offer durable performance, providing value over time.

A: An industrial centrifugal fan is a mechanical device used to move air or gases in industrial applications. It generates airflow by converting rotational energy into kinetic energy through centrifugal force.

A: To choose the right centrifugal fan, evaluate your facility's airflow requirements (CFM), pressure needs, and environmental conditions. Consider the fan's energy efficiency, noise levels, and maintenance needs.

A: Backward inclined centrifugal fans offer higher efficiency, produce less noise, and can handle higher static pressures. They are ideal for industrial exhaust systems and dust collection.

A: The right centrifugal fan can reduce energy consumption and maintenance costs. Energy-efficient fans lower electricity bills, while durable designs reduce the need for frequent repairs and replacements.

A: Regular maintenance for a centrifugal fan includes cleaning, checking for wear and tear, lubricating moving parts, and inspecting for blockages. Proper upkeep extends the fan’s lifespan and ensures optimal performance.