close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-29 Origin: Site

When it comes to industrial fans, two of the most commonly used types are axial fans and centrifugal fans. These fans are designed to move air, but they differ significantly in their construction, design, and applications. Understanding the differences between these two types of fans is crucial for selecting the right fan for your needs. In this article, we will dive deep into the distinctions between axial fans and centrifugal fans, their working principles, advantages, applications, and much more.

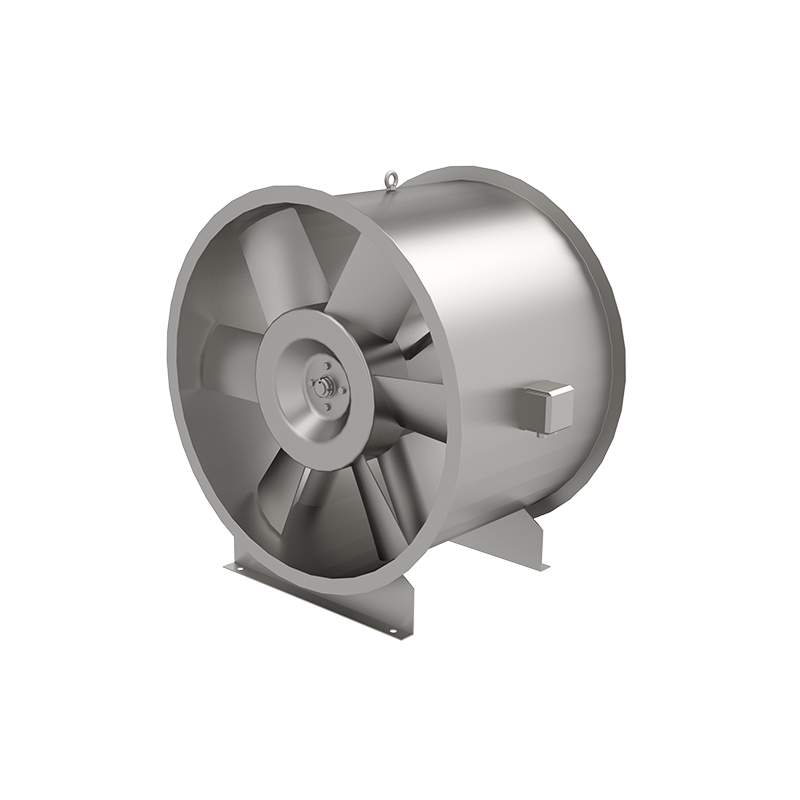

Axial fans are a type of mechanical fan where the air flows along the axis of rotation. These fans are characterized by blades mounted on a central hub, which rotate to push air parallel to the axis of the fan. The airflow generated by axial fans is typically high volume but low pressure, making them ideal for applications where large amounts of air need to be moved across a short distance.

High Airflow: Axial fans are designed to move large volumes of air.

Low Pressure: They provide low-pressure airflow, which is suitable for ventilation or cooling applications.

Simple Design: The design of axial fans is straightforward, making them easy to manufacture and cost-effective.

Energy Efficiency: These fans are often more energy-efficient than other types because of their simple construction.

Axial fans are used in a variety of applications, such as cooling towers, ventilation systems, and exhaust fans in industrial environments.

Centrifugal fans, on the other hand, work by drawing air into the center of the fan and then expelling it at a right angle, usually through a spiral-shaped housing. The airflow generated by centrifugal fans is typically higher pressure but lower volume than that of axial fans. These fans are commonly used where higher air pressure is required, such as in duct systems or in applications that need to overcome resistance.

High Pressure: Centrifugal fans generate higher pressure, which makes them ideal for duct systems and applications with higher resistance.

Compact Design: Due to the centrifugal motion, these fans can achieve higher pressures with smaller designs.

Versatility: Centrifugal fans are used in a wider range of applications due to their ability to handle higher pressures.

Higher Energy Consumption: In some cases, centrifugal fans consume more energy than axial fans due to their more complex design.

Centrifugal fans are found in applications such as HVAC systems, industrial blowers, air purifiers, and exhaust systems.

One of the primary differences between axial fans and centrifugal fans is the direction of the airflow. Axial fans move air parallel to the axis of rotation, while centrifugal fans move air at a right angle to the direction of the intake.

| Fan Type | Airflow Direction |

|---|---|

| Axial Fans | Parallel to the axis |

| Centrifugal Fans | At a right angle to the intake |

Axial fans typically generate low pressure and are used in applications where airflow is the primary concern. On the other hand, centrifugal fans produce higher pressure, making them suitable for systems that require the movement of air through ducts or systems with high resistance.

| Fan Type | Pressure Generation |

|---|---|

| Axial Fans | Low pressure |

| Centrifugal Fans | High pressure |

Axial fans are generally more efficient at moving large volumes of air with minimal power consumption, thanks to their simple design. In contrast, centrifugal fans tend to be less efficient in terms of energy consumption because of the complexity of their design and the need for more power to overcome resistance.

| Fan Type | Efficiency |

|---|---|

| Axial Fans | High efficiency, low power |

| Centrifugal Fans | Lower efficiency, higher power |

Axial fans tend to have a larger diameter and are longer in shape. They are simple to manufacture and typically cost less to produce. Centrifugal fans, on the other hand, tend to have a more compact design but require more complex engineering and can be bulkier depending on the required pressure levels.

| Fan Type | Design |

|---|---|

| Axial Fans | Larger, simpler design |

| Centrifugal Fans | More compact, complex |

Axial fans tend to produce more noise due to the high volume of air moving through the blades. The design of centrifugal fans allows them to operate at lower noise levels, especially in applications where noise is a significant concern.

| Fan Type | Noise Levels |

|---|---|

| Axial Fans | Higher noise |

| Centrifugal Fans | Lower noise |

Axial fans are most commonly used in applications that require high airflow at low pressure. These include:

Cooling Towers: In industrial cooling systems, axial fans are used to move air through the cooling towers to dissipate heat.

Ventilation Systems: Axial fans are widely used for ventilation in industrial and commercial buildings.

Exhaust Systems: In industries where large amounts of air need to be removed, axial fans play a vital role.

Computer and Electronic Equipment: These fans are often used in cooling systems for computers, electronics, and power plants.

Centrifugal fans are best suited for applications that require higher pressures and can handle ductwork or high-resistance systems. Some common applications include:

HVAC Systems: In heating, ventilation, and air conditioning, centrifugal fans are often used to circulate air through ductwork.

Industrial Exhaust: Centrifugal fans are used in industries that need to move air through pipes, ducts, or hoods, such as in fume extraction or material handling systems.

Air Purifiers: The high-pressure capabilities of centrifugal fans make them ideal for air filtration and purification systems.

Blowers: Centrifugal fans are widely used in blowers for pneumatic conveying systems in industries like cement, food, and pharmaceuticals.

High airflow capacity: Excellent for large-scale ventilation and cooling applications.

Lower cost: Simpler design makes axial fans more cost-effective.

Energy-efficient: Low-power consumption makes them ideal for energy-conscious systems.

Low pressure: Not suitable for systems with high resistance or long ducts.

Higher noise levels: The large volume of air moved can result in higher noise production.

High pressure: Ideal for systems requiring high pressure, such as HVAC and industrial exhaust.

Compact design: Requires less space compared to larger axial fans.

Versatility: Can handle ductwork and more complex systems.

Higher energy consumption: Due to their more complex design.

Higher cost: More expensive to manufacture than axial fans.

Lower airflow: Not as efficient at moving large volumes of air as axial fans.

The main difference is that axial fans move air parallel to the axis of rotation, whereas centrifugal fans move air at a right angle to the intake.

Centrifugal fans are better suited for high-pressure applications due to their ability to generate more pressure.

Yes, axial fans are typically more energy-efficient for applications that require high airflow but low pressure.

Yes, centrifugal fans are commonly used in ventilation systems that require moving air through ducts or systems with higher resistance.

Centrifugal fans tend to be quieter compared to axial fans due to their design and the way air is moved through the system.