close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-02-04 Origin: Site

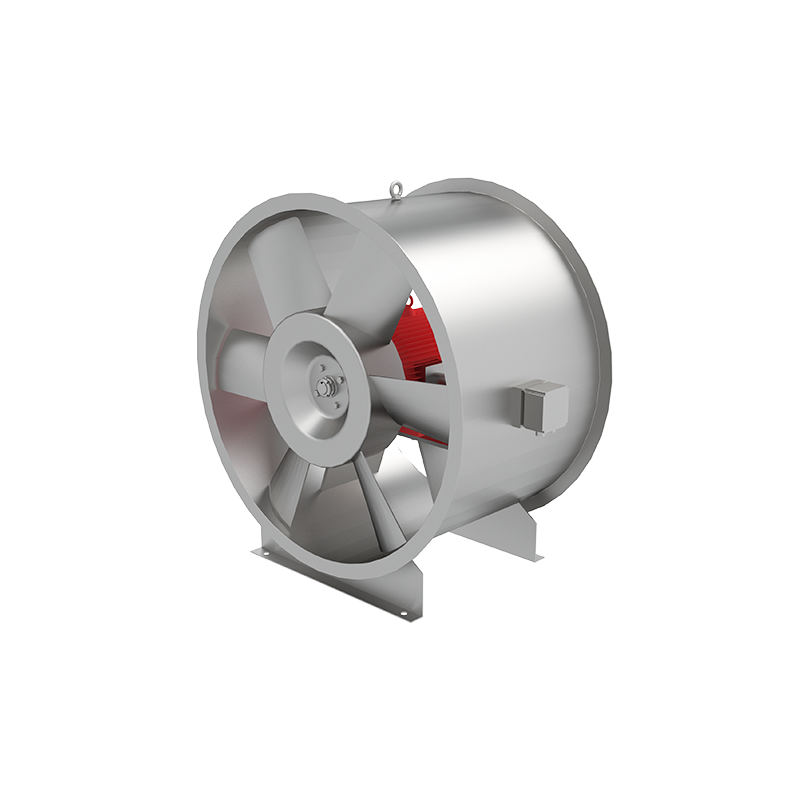

Industrial axial fans are an essential component in many industries where airflow is crucial for maintaining optimal operating conditions, cooling processes, or ventilating spaces. From large-scale manufacturing facilities to commercial buildings and specialized applications such as exhaust and cooling towers, choosing the right axial fan can make a significant difference in performance, energy consumption, and cost-effectiveness. This article will provide a comprehensive guide on how to select the most suitable axial fan for your industrial needs, exploring various factors such as efficiency, size, installation, and performance.

Axial fans are a type of mechanical fan where the airflow direction is parallel to the axis of the fan. The fan blades rotate to move air through the system, and the amount of air moved depends on the size, speed, and design of the fan. These fans are commonly used for applications that require high airflow with relatively low pressure, such as ventilation, cooling, and exhaust systems.

High airflow capacity: Designed to move large volumes of air efficiently.

Low pressure: Ideal for situations where air needs to be moved over a relatively short distance and at a low pressure.

Simple design: Typically consist of a rotating set of blades attached to a central hub, making them easy to manufacture and maintain.

Energy-efficient: Thanks to their design, axial fans are more energy-efficient compared to other fan types when used in low-pressure applications.

Cooling towers

HVAC systems

Exhaust ventilation systems

Industrial cooling processes

Clean room ventilation

Industrial axial fans are designed to provide a reliable and efficient airflow, but choosing the right fan requires understanding several key considerations.

Choosing the right axial fan for your industrial application requires a detailed understanding of the operational conditions, airflow requirements, and environmental factors. Below are the essential considerations when selecting an axial fan.

The first and most important factor to consider is the airflow required for your application. Airflow is typically measured in cubic feet per minute (CFM) or liters per second (L/s), and it indicates the volume of air that the fan needs to move in a given time period.

Volume of space to ventilate: The size of the area that needs to be ventilated will determine the airflow capacity needed.

Required ventilation rate: In industrial environments, specific ventilation standards must be met to ensure safe working conditions.

Airflow uniformity: Some applications, such as cooling towers, require even distribution of airflow, which can influence the choice of fan type and configuration.

Axial fans are known for producing low pressure, making them ideal for systems where the airflow needs to travel through short distances or through non-restrictive ducts. If your system requires high pressure, you might need a centrifugal fan instead. However, for axial fans, the pressure can still vary based on the fan design and operating conditions.

System resistance: If your system has ducts, filters, or other resistance components, you will need to choose an axial fan that can generate enough pressure to overcome these restrictions.

Desired pressure increase: Determine the pressure needed to achieve the desired airflow velocity.

The size of the axial fan is crucial in determining its efficiency and suitability for your application. Larger fans typically have a greater airflow capacity, but they may also require more space for installation.

Fan diameter: The larger the fan diameter, the higher the airflow capacity. However, larger fans may require additional support structures and may increase installation costs.

Blade configuration: The number and shape of the blades can significantly influence the airflow and efficiency of the axial fan. Some axial fans are designed with specially shaped blades to increase airflow while reducing noise levels.

Mounting style: Fans can be mounted in various configurations, such as in-line, ceiling-mounted, or floor-mounted, depending on your specific needs.

In industrial settings, energy efficiency is a key factor in reducing operational costs. Axial fans are generally more efficient than other types of fans, but the fan’s efficiency will still vary depending on the design, motor type, and operational conditions.

Motor type: Choosing a high-efficiency motor, such as a variable frequency drive (VFD), can help reduce energy consumption by adjusting fan speed to meet demand.

Fan blade design: The aerodynamic design of the blades can reduce drag, improving efficiency. For example, curved blades can improve airflow and reduce turbulence.

Variable-speed options: If airflow demand fluctuates, a fan with variable-speed control will allow for more efficient operation.

Noise can be a significant concern, especially in environments where workers need to be able to communicate or where the fan is located in a noise-sensitive area. Axial fans can be relatively noisy, particularly when used in high-flow or high-speed conditions.

Noise reduction features: Some axial fans are designed with noise-reducing features such as silencers, special blade designs, or vibration-dampening materials.

Fan speed: Lower fan speeds generally result in quieter operation.

Location of installation: Consider the installation location and whether noise reduction measures such as enclosures or soundproofing will be required.

The environmental conditions in which the fan will operate are critical to its longevity and performance. For instance, fans used in outdoor environments, corrosive areas, or high-temperature settings need to be durable and resistant to specific challenges.

Corrosion resistance: Fans installed in corrosive environments, such as those near saltwater or in chemical plants, should be made of corrosion-resistant materials such as stainless steel or treated alloys.

Temperature tolerance: Some axial fans are designed to handle high-temperature environments, such as cooling systems in industrial processes.

Explosion-proof models: In environments with hazardous gases or dust, explosion-proof models of axial fans are essential to ensure safety.

The lifespan of an axial fan and the ease of maintenance can significantly affect operational costs. Choosing a fan that is easy to maintain and has a long service life can reduce downtime and extend the fan’s operational efficiency.

Motor maintenance: Look for fans with easily accessible motors and parts that can be serviced or replaced without significant downtime.

Bearing design: The type of bearing used in the fan can affect its lifespan and maintenance needs.

Regular cleaning and lubrication: Ensure that the fan design allows for easy cleaning and lubrication to prevent wear and tear.

To further assist in choosing the right axial fan, let's compare different product types available in the market. Below is a comparison of three common axial fan models, with different features and specifications.

| Product | Airflow Capacity (CFM) | Pressure (inches of H2O) | Motor Type | Noise Level (dB) | Energy Efficiency | Applications |

|---|---|---|---|---|---|---|

| HL3-2A Type Axial Fan | 20,000-60,000 CFM | 0.5-1.2 inches H2O | Single-speed / VFD | 70-75 dB | High | Cooling towers, industrial ventilation |

| PYHL-14A Fire Smoke Exhaust Fan | 15,000-40,000 CFM | 1.0-2.5 inches H2O | VFD / explosion-proof | 75-80 dB | Moderate | Fire and smoke exhaust, hazardous areas |

| SWF Series High-Efficiency Fan | 10,000-50,000 CFM | 0.3-0.8 inches H2O | VFD, dual-speed | 65-70 dB | Very High | HVAC, industrial air handling systems |

HL3-2A: This fan offers a high airflow capacity and is designed for use in cooling towers and general ventilation. It is equipped with a variable-frequency drive (VFD) for energy efficiency.

PYHL-14A: Designed for fire and smoke exhaust, this fan is rated for high-pressure environments and comes with explosion-proof options for hazardous areas.

SWF Series: Known for its energy efficiency, this fan is ideal for HVAC systems and industrial air handling applications. Its low noise level and high efficiency make it an excellent choice for sensitive environments.

Axial fans move air along the axis of rotation, providing high airflow at low pressure. Centrifugal fans, on the other hand, move air at a right angle to the intake, generating higher pressure. Axial fans are more suited for ventilation, while centrifugal fans are ideal for systems with higher resistance.

To determine the required airflow, calculate the volume of the space that needs ventilation and the number of air exchanges required per hour. This information is often specified in air handling system guidelines or industry standards.

Axial fans are generally not suitable for high-pressure applications due to their design. For higher pressure, a centrifugal fan would be a better choice.

You can reduce noise by choosing an axial fan with noise-reducing features such as silencers, specially designed blades, or lower-speed motors. Additionally, placing the fan in a soundproof enclosure or isolating vibrations can also help reduce noise.